Whether it’s for defense, commercial, or pleasure sailing, high-performance vessels are expected to have enough dynamic power to transition quickly between low-speed maneuvering and high-speed cruising.

This requires high engine power over a broad range of engine rotational speeds, so a high-speed engine must provide high power density, good transient response, high efficiency, and optimal performance over a broad range of operating conditions—all at once.

Translated into turbocharging requirements, this means high compressor pressure ratios corresponding to higher power density and a wide volume flow range to suit various engine speeds. However, there’s a trade-off. High compressor pressure ratios result in a narrower range of volume flows, which can limit boost pressure available at low engine speeds.

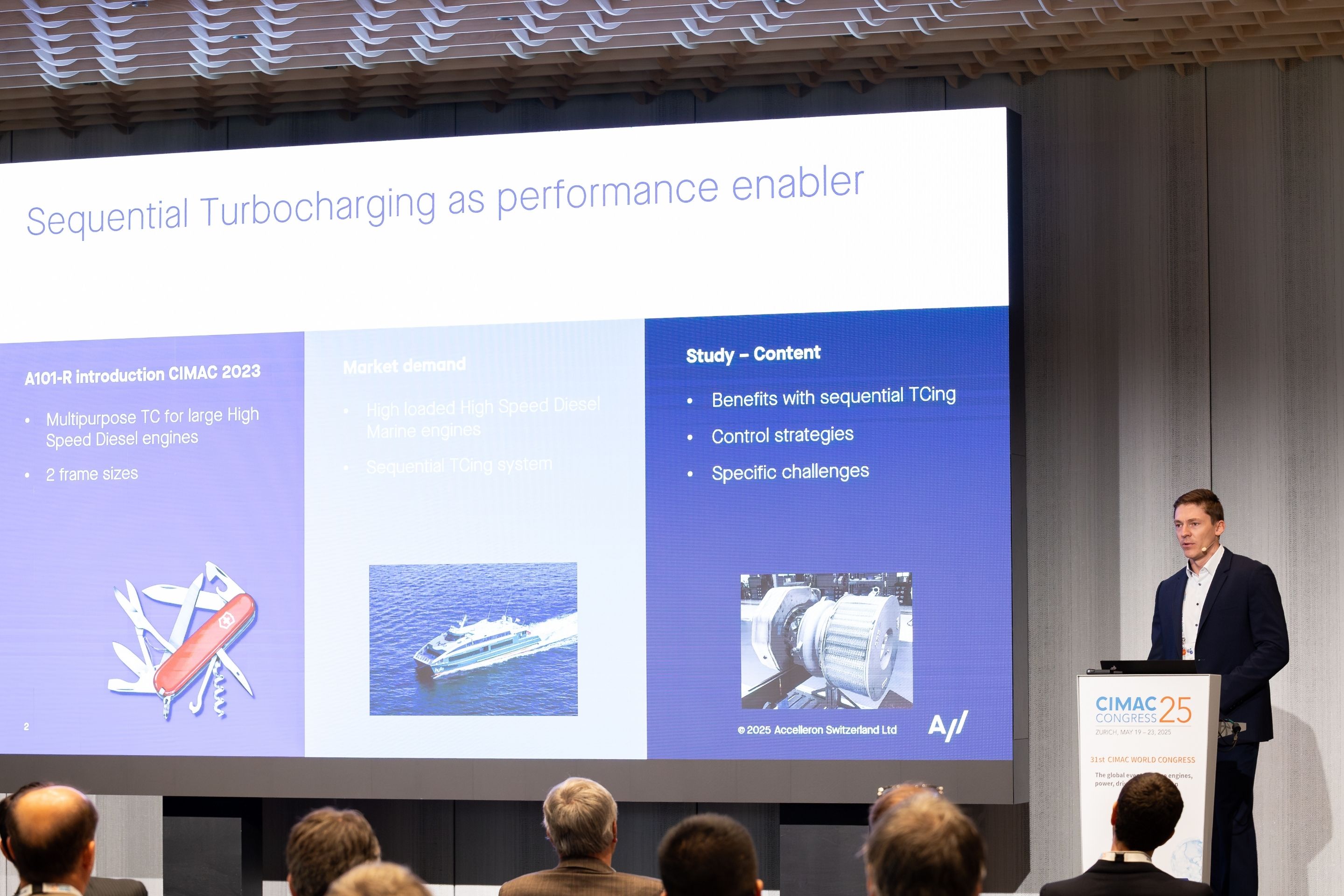

Accelleron Manager OEM Sales & Application Engineering Cyril Bessonnard presented an update on the company’s solution to the challenge, the new A101-R multi-purpose turbocharger series, at CIMAC Congress 2025—hosted by Accelleron—in Zürich in May.

Cyril Bessonnard presenting at CIMAC 2025

Designed to outperform

Initial research confirmed the benefits of sequential turbocharging over wastegate systems (where a valve controls enabling the exhaust gases to by-pass the turbine controls boost pressure). Sequential turbocharging activates two or more turbochargers in turn to provide higher pressure ratios and expanded volume flow range. Sequential turbocharging enables cutting-out one or more turbochargers to provide the highest compressor pressure ratios from the lowest volume flow range. With turbocharger cut-out, as the total engine flow is directed to fewer turbocharger units, the “activated“ turbines benefit from higher exhaust mass flow, thus enabling better transient response.

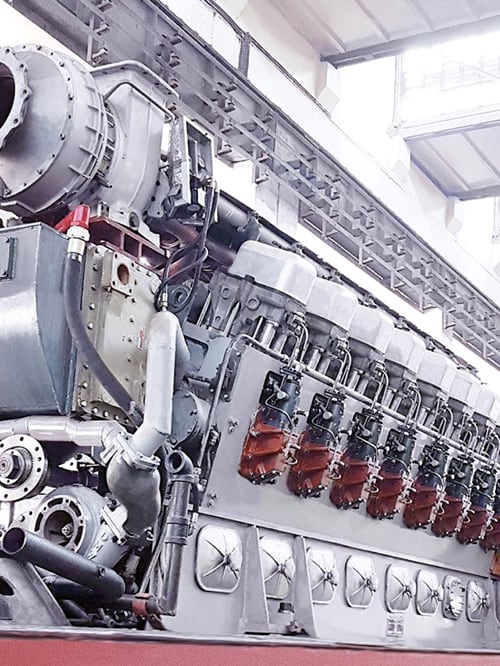

Accelleron’s development team focused their attention on improving the high performance already obtained by the established A100-H single-stage turbocharger series. The result is the A101-R series, featuring a new turbine stage, a robust bearing and shaft sealing system, optimized bearing to turbine casing joint, and a modular compressor design.

The compressor has a high pressure ratio capability, while the new turbine stage enables higher rotational speeds than the existing A100 turbines. The A101-R also has increased ability to provide the air needed for combustion during the cut-in process of the second turbocharger.

The highest power density of BMEP over 30 bar is enabled, and a large range of matching material also enables fine tuning of the operation line. This reduces compromise imposed at switching points caused by limitations such as the surge line, speed limit, or lower-efficiency zones. In cyclical load profiles, part-load optimized performance and high specific flow capacity improve cut-in and acceleration.

“A part load optimized turbine efficiency, coupled with a turbine flow that provides low effective areas at low expansion ratios, permits better part load performance”.

“A turbine with high specific flow capacity enables a reduction of the turbine wheel diameter and thus reduces inertia”. says Bessonnard. “Also enabling faster acceleration of the turbocharger”.

Oil leakage into the compressor and turbine casings of the non-activated turbochargers can occur in sequential turbocharger applications, especially during the cut-out switching process where a negative pressure difference between the compressor backwall and bearing casing can arise. To prevent this, the A101-R features a further improved shaft sealing system compared to the A100-H.

To maintain the casing positioning and gas tightness with significant relative movement between the casings—which can arise during deep thermal cycles—the A101-R was designed with an optimized turbine-to-bearing casing joint connection together with a reinforced clamping system. The new design was extensively validated on a test rig as well as on field engines operated with many thermal cycles.

The end result is that the A101-R can, for example, increase operating speeds for high cyclical applications by 11% by enabling a 30% increase in achievable compressor pressure ratio and a 27% improvement in specific flow capacity.

Cyril Bessonnard, CIMAC Congress 2025

Cyril Bessonnard, CIMAC Congress 2025

Marine performance goals

For marine propulsion engines, performance over a wide range of loads and speeds is required to satisfy all the conditions a vessel could meet during its operation. These vary from constant speed to quick acceleration requirements in different sea conditions, and with capabilities for towing or carrying different tonnage.

“In marine applications, high power density is particularly critical to enabling high power output without adding excessive weight that would reduce fuel efficiency,” says Bessonnard. “In addition, high power density reduces engine footprint, enabling designers to focus on passenger, cargo, and equipment areas.”

Marine engines must provide the power needed to overcome the hydrodynamic resistance of the propeller and hull at varying speeds and environmental conditions.

Built to last

The greater complexity of sequential turbocharging systems and the higher operating speed of the A101-R necessitates greater validation efforts, says Bessonnard, particularly for high and low cycle fatigue and maximum material temperatures.

In addition to an internal qualification process, Accelleron performed field validation to further confirm the correct operation of its turbocharger units on end-user applications. Inspections have been performed after 3,000 and 5,000 running hours on various installations. First inspections have been performed on a rail application, the most demanding for a turbocharger, showing promising results.

Special attention has been given to the axial thrust bearing when the engine breathing line is operating far from the standard propeller line, which is typically the case for sequential turbocharging.

“The thrust load depends on the operation point in the compressor map, and in some cases, it can even reverse from the main to the auxiliary thrust bearing. Consequently, a strong axial bearing system assures reliability,” says Bessonnard.

A versatile solution

The new A101-R platform currently features two frame sizes that suit 12 to 20V-cylinder engines, and an option for two-stage. Five compressor versions cover engine power ratings from about 900kW to around 2,000kW per turbocharger. A dedicated application package has been developed to answer the specific challenges of each application sector: power, oil and gas, marine, and off-road.

Commercial deliveries of the A101-R have now commenced for numerous engine builders worldwide.