People are often surprised that turbochargers can be so loud. The noise of the turbocharger is higher in frequency than engines and more noticeable than the rhythmic signature of propellers.

“It's characterized by a whining or whooshing sound, often perceived as sharp or metallic due to the fast-moving compressor blades,” says Accelleron R&D Engineer Carsten Spinder. “The high-frequency tonal component, especially at faster rotational speeds, can be intrusive, because it falls within the acoustic frequencies of human speech, so our hearing is very sensitive to it.”

Without silencers, turbochargers can thus reach sound pressure levels that are uncomfortable for the human ear, and engine rooms on board ships can exceed the limits typically set for landside power stations.

Since excessive exposure to these levels of noise can potentially contribute to hearing impairment, hypertension and sleep disorders, and the UK P&I Club rated hearing defects as the eighth most common reason for seafarers failing pre-employment medical examinations in the year ending December 2024, regulations aim to set limits on noise levels to prevent such impact.

Although Accelleron’s silencer technology already exceeds current regulatory requirements, advancements in simulation models open up another level of possibility for advanced silencer protection.

Sonic signatures

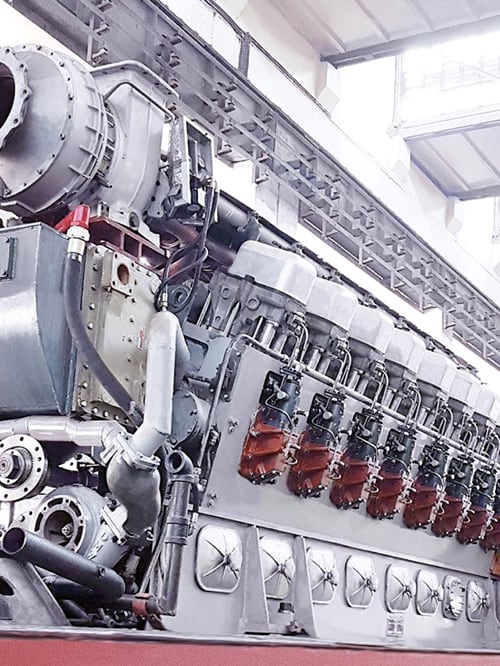

The noise from turbochargers comes from a combination of movements, including the whirring of the compressor blades, surging or stalling in compressors, acoustic resonance in pipes, and structural vibrations. Flow instabilities and aerodynamic mismatches can also contribute to the noise.

Acoustic signatures vary between different turbocharger types and engine models. The pressure pulses, duct geometries, and exhaust layouts of different engines can interact differently with turbocharger noise, either amplifying or dampening specific frequencies. Structural resonance can also amplify noise, so understanding acoustic-structural coupling is important in the development of silencers and dampening strategies.

In ship engine rooms, isolated engine noise levels are typically about as loud the noise from the turbochargers alone. However, since engine has a lower frequency, it can travel further onboard and through the water. So, although turbocharger noise can be acute for humans at close quarters, it does not travel as far as engine or propeller noise. “It is therefore largely the occupational risks to workers that we focus on in our silencer performance targets,” says Spinder.

The science of silence

To dampen the turbocharger noise, special foams and geometrically optimized metallic panels are layered into a silencer located at the compressor inlet. At the outlet, where temperatures are higher, resonators are tuned to nullify sound at specific frequencies. That helps to avoid structural resonance which could otherwise amplify the turbocharger noise.

“Our customers take turbocharger noise very seriously, and they make sure that it is under the regulatory limits, because otherwise they will not be able to qualify their engines. We want to push the boundaries of research now to support advanced protection for seafarers, so that our customers can offer better protection that remains well ahead of regulation,” says R&D Engineer Maaz Farooqui.

The most challenging aspect of current efforts is to accurately predict acoustic behavior under real-world conditions, he says. “Accelleron has a long history, over 100 years, in turbocharger acoustics research and silencer design. In the past, noise propagation predictions were heavily based on physical lab experiments, so it took significant time to design, test, and validate new concepts. As we shift to computer simulation, we can not only expand the acoustic possibilities, but we also aim to accelerate the overall experimentation and testing process,” says Farooqui.

Applying highly accurate acoustic modelling, rig testing, and design optimization enables swift and precise validation of new design concepts. This speeds up the entire development and testing process, as the team seeks to develop even more precise silencer and dampening capabilities.

A metamaterial impact

The emergence of “metamaterials” is also opening up greater noise reduction potential.

In traditional silencers, the bulkiness of noise dampening materials, combined with the space constraints and high temperatures of environmental conditions, can set a certain limit on silencing capability and efficiency.

So, the acoustic team is also continuously exploring new acoustic metamaterials, which exhibit exotic properties not found in natural materials. Metamaterials are comprised of plastic, metal, or foam – or a combination of materials. Engineers then shape them into special tiny structures with cavities or holes, further formed into membranes or thin sheets with coiled or zig-zag channels to create extraordinary acoustic properties. The magic comes from patterns and geometry, not the material itself. Think of Lego bricks as natural materials and metamaterial is a product made of Lego blocks.

These new metamaterials can be significantly more compact and resilient to heat, opening up new acoustic absorption possibilities. “Metamaterials have extraordinary properties. To mitigate noise with a frequency of 1,000 Hertz, we currently need foam of a substantial thickness of several centimeters. With metamaterial technology, we could reduce the thickness by 80-90%,” says Farooqui.

Present and future outlook

Baseline measurements have now been completed for a new silencer concept, and the Accelleron team is beginning to conduct validation activities to make this new concept applicable to various platforms. Integration trials on Accelleron’s measurement rigs will then involve assessment of both efficiency and cost for dedicated applications.

“Our focus on advanced acoustic solutions is driving us toward smarter and more sustainable product qualification,” says Farooqui. “By solving noise challenges efficiently and improving acoustic performance from the start, we enable faster, cleaner, and more resource-efficient development. Better acoustics not only enhance product quality, they also help us build a quieter, more sustainable future.”