Net-zero shipping will be built on energy efficiency to 2030 and carbon-neutral fuels to 2050. New regulations and financial penalties will push adoption of both at an accelerated pace.

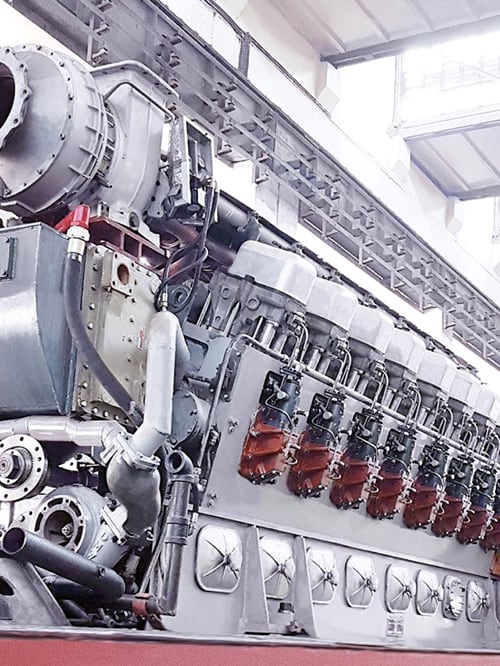

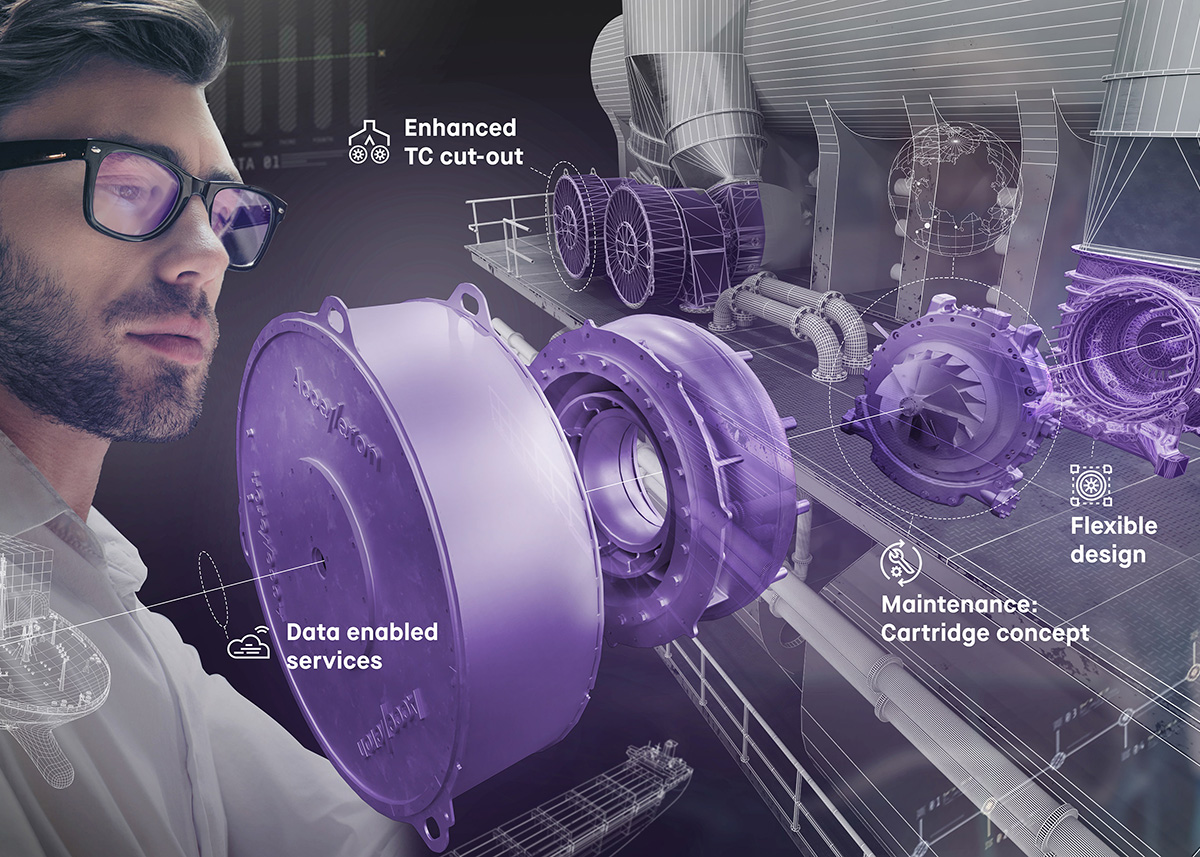

The increasing pressure on shipowners is driving accelerated product development at Accelleron as flexibility and the future viability of assets becomes ever more important. In 2023, Accelleron unveiled a new generation of turbochargers, the ACCX300-L series. That development is now being rolled out—and with it comes a shift in design approach that prioritizes the future needs of shipowners whilst still meeting the requirements of engine manufacturers.

The benefits of the ACCX300-L series stem from its compact, platform-based design, making it easy to adapt to lower vessel speeds, easy to service, and ready for carbon-neutral fuels such as green methanol and ammonia.

The new turbocharger generation integrates compressor specifications for 2-stroke and 4-stroke applications within one concept and currently comprises the ACCX365-L and ACCX370-L frame sizes. Technology qualification has been ongoing ahead of first deliveries at the end of 2026.

Simon Ma presenting at CIMAC 2025

Greater operational efficiency

Many ship operators have adopted slow steaming to reduce emissions, in order to meet the initial requirements of regulations such as the IMO’s Carbon Intensity Indicator. This practice can also help shipowners reduce the cost of running on less energy-intensive, more expensive, carbon-neutral fuels.

Engines and turbochargers need to optimize efficiency across a wider operational range, and the ACCX300-L series is prepared for turbocharger cut-out. Cutting out one turbocharger at lower engine loads results in higher scavenging air pressure, higher compression ratio, and higher firing pressure—resulting in higher engine efficiency and lower specific fuel consumption. There is also the potential for switching off auxiliary blowers to further reduce energy consumption.

Accelleron’s solution is the Flexible integrated Turbocharging System for 2-Stroke Engines (FiTS2) system, which provides a turnkey solution for fully automated cut-out and cut-in operation via an in-house developed Control Unit interfacing with the engine control.

Simon Ma, Product Manager at Accelleron, presents an update on the new ACCX300-L turbocharger series at CIMAC Congress 2025, in Zürich in May. He explains: “FiTS2 uses a smart combination of unequally specified turbochargers and wide compressor maps. Two or more turbochargers operate in sequence for optimum air delivery at each engine load. This optimizes engine fuel consumption at part and low load while maintaining the flexibility to go to full engine output immediately.”

Simon Ma, Product Manager, Accelleron, CIMAC Congress 2025

Simon Ma, Product Manager, Accelleron, CIMAC Congress 2025

Reduced operating expenses

The ACCX300-L series is built on a platform approach that maximizes modularity. An easily exchangeable cartridge contains all rotating parts. This allows the extraction and installation of the turbocharger core without further dismantling from either the compressor or turbine side. All casing connections are axially accessible within the box volume of the turbocharger once the air outlet is dismantled. The cartridge, including packaging for transportation, is designed to fit on a standard shipping pallet.

The cartridge concept is particularly valuable for cut-out operation, says Ma. “The turbochargers participating in the cut-out operation will have a different utilization to those that are not, and hence the existence of different maintenance needs for turbochargers on the one vessel. The X300-L turbocharger series leverages its cartridge concept for vessel operators to satisfy these varying maintenance needs with major service events possible during port stay in addition to dry dock.”

Instead of servicing turbochargers every five years, the ability to exchange cartridges in port means the full runtime between overhauls can be used, resulting in increased service intervals and lower operating costs.

Future fuel flexibility

Accelleron’s ACCX300-L series turbochargers feature feature an advanced turbine and compressor stage designed with increased specific flow capacity and higher pressure ratios. High efficiency at part load and at full load — up to a pressure ratio of 5.0 — results in an optimal turbocharging solution for a broad range of ship power configurations.

To serve higher engine power needs, Accelleron has developed the TWIN concept - parallel combinations of smaller and lighter turbochargers in various unconventional pairings of the ACCX365-L and/or ACCX370-L models. This brings the benefits of the cartridge concept to even higher engine power where the cartridge weight, transportation and job duration requirements from larger frame sizes are likely otherwise prohibitive. It also creates additional options for potentially more complex engine configurations and more opportunities for turbocharger cut-out.

Physical verification of the final product is key to achieving this next level of power density, so Accelleron’s qualification process has included thermos-mechanical integrity testing and performance checks and confirmation of reliability against high and low cycle fatigue. Other testing has included analysis of the sealing air system and checks for non-uniformity of the inflow into the filter silencer. An investigation into the impact of ammonia-rich gases on turbocharger materials has also been undertaken.

Ready for the future

The IMO recently reported that the carbon intensity of the international shipping fleet dropped 5-10% between 2019 and 2023. The latest ACCX300-L turbochargers will help shipowners accelerate their achievements and meet the decarbonization challenges ahead.