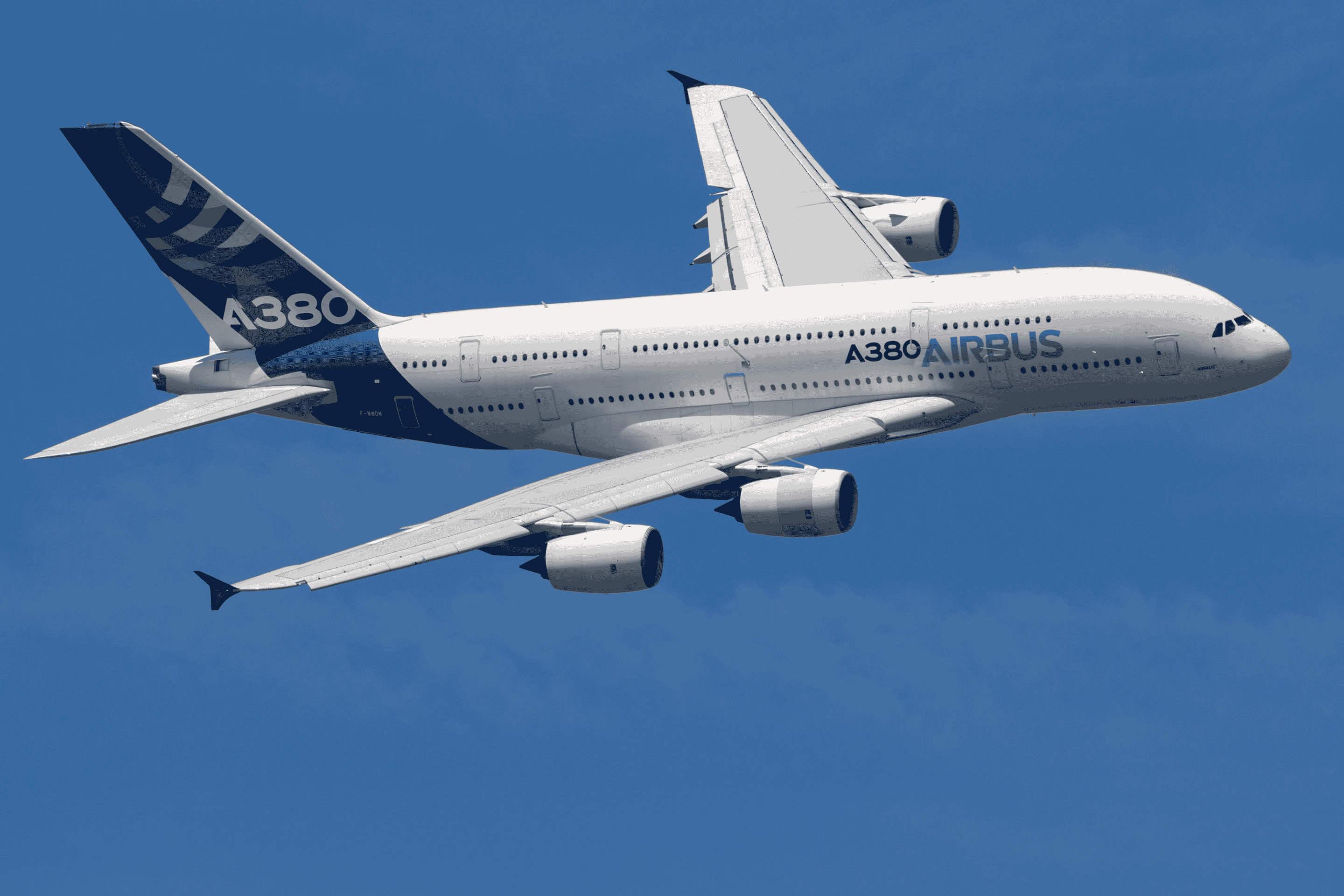

Modern aircraft are a miracle of logistics. Take the world’s largest commercial passenger plane, the Airbus A380. Until production ceased in 2021, it was made of 4 million distinct parts supplied by 1,500 companies in 30 countries. Getting components to the production site in Toulouse meant transporting most of those pieces by sea to the port of Pauillac in France. That required specialized vessels, and a special focus on making the supply chain as efficient as possible.

In 2002, in order to satisfy the growing A380 order book and in anticipation of further growth, Airbus entrusted Louis Dreyfus Armateurs and its subsidiary LD Seaplane with the design of ro-ro ships that could be dedicated to such transportation. The vessels were designed to ferry A380 components between the manufacturing facilities and assembly point, all located on mainland Europe. When the A380 was phased out, the fleet was adapted for different runs.

The LD fleet now transports many components for the A320, which recently surpassed the Boeing 737 as the highest selling airliner of all time—and has perhaps an even more convoluted supply chain than the A380. While most of the fuselage sections are manufactured at the same facilities in Europe that service the A380, for some A320s the final assembly point is in Mobile, Alabama and so the components must be sailed across the Atlantic.

Mitigating weather disruption

Given the seasonal unpredictability of the Atlantic this crossing poses a threat to maintaining Airbus’ tight production schedule. The Mobile facility can finish four A320s monthly and it is paramount that the assembly lines remain in operation to ensure on-time delivery, which means that a full set of components must be delivered to the plant each week.

It is easy to imagine how delays might be incurred during the trip from Toulouse to Mobile. A hurricane in the South Atlantic could force one of the vessels to deviate course or shelter while waiting for the storm to pass. A single delay is undesirable and, given the frequency that LD conducts this run, the risk posed by the crossing is magnified. But because of the size and delicacy of the fuselage there are few practical alternatives to sea transport.

Aside from the route to Mobile, LD Seaplane also conducts voyages from Montoir to Naples and Montoir to Tunis to transport sub-assembly components between Airbus’ dispersed production sites. Travel through the Mediterranean and up the Spanish coast can also be unpredictable, particularly in the fall and winter when low pressure systems batter the Bay of Biscay and so weather routing for these voyages is no less important.

The risk of weather disruption can be effectively managed by a weather routing solution that can foresee and adapt to hazards during the crossing. Accelleron company True North Marine (TNM) works closely with LD Seaplane to ensure that the vessels make it to destination safely and within their respective schedules. While LD addresses the transportation challenges for Airbus, TNM helps manage many of the potential disruption risks along the way.

Human in the loop

TNM delivers expert-led, data-driven route planning to ensure on-time, cost-effective voyages and fuel-efficient operations. The AI-powered service helps customers deliver goods faster and more efficiently while reducing costs and risks. Now joining forces with Accelleron’s vessel optimization solutions, the result is unique visibility, control, and support across every aspect of vessel and voyage performance.

The TNM solution is more than just software, with a ‘human-in-the-loop’ approach that depends on expert oversight. Ultimately any supply chain hinges on effective communication between the various parties and even the best laid plans can unravel in the face of misunderstanding or mistrust. TNM has therefore strived to build a rapport with the most critical element of these ships: the captains.

The exceptional relationship between LD Seaplane ship captains, shore operators and TNM helps make voyage after voyage free from delay—playing a critical role in connecting various aspects of Airbus’ supply chain. Through its partnership with LD, TNM minimizes the risk of delay and helps to ensure that delivery and production schedules are upheld. This is particularly important for complex supply chains like Airbus, and by building durable relationships with the partners involved TNM is able to ensure successful and delay-free voyages.