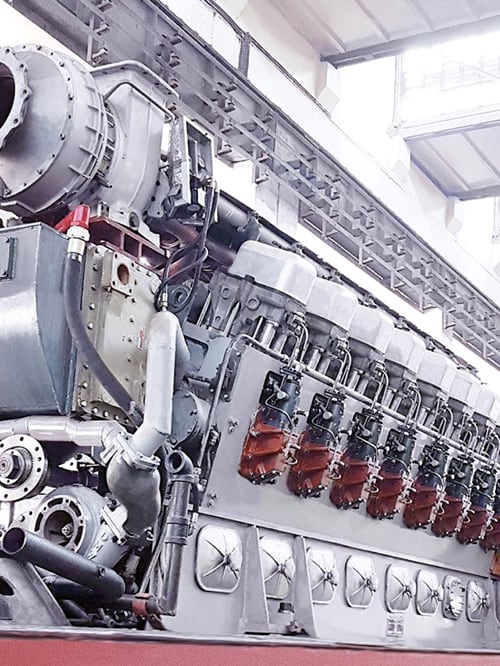

Cameroon’s electricity production is split into two separate grids, serving the north and south of the country. Kribi is a gas-powered facility in the south that generates 20-25% of the region’s energy. It complements hydroelectric power stations, including Song Loulou,² particularly during periods of high demand or when water levels in reservoirs are insufficient for hydroelectric generation.

Kribi Director, Charles Kissinger Ngoug, explains, “The main key performance indicator for Kribi is availability. We are paid by the grid operator based on our capacity charge, and we need to ensure that engines are available to generate power at any given time. Even if the grid operator does not require power from Kribi, we must be ready to supply it to the grid when needed. If we are not available, we do not get paid.”

This means that downtime must be kept to a minimum, and Kribi has a 4% maximum allowance for forced outage. Although the plant operates within such margins, there’s always a concern that aging equipment could lead to unexpected issues.

“To maintain uptime, we are looking ahead to carry out proactive maintenance, as we want to be ready and avoid situations where we have a forced outage. We want to be able to plan when we stop the engine for planned maintenance and replace everything necessary to keep the plant running reliably without issues.”

Parts availability is particularly important to Kribi, and Charles highlights the case of a foreign object damaging one of the plant’s engines as an example of why it’s so critical. The repair solution included the complete replacement of one set of the turbine blades, with parts only available in Switzerland. “There are fewer spare parts available on the local market in Cameroon when compared to Europe, and a strong supply chain is needed to ensure that spare parts are delivered on time. In this case we were covered by the Turbo LifecycleCare agreement, and able to receive the part in just a day or two, rather than weeks.”

A long-standing relationship

Accelleron has been helping Kribi to maintain reliable operations, which its customers depend, on since 2018, when Globeleq signed its first Turbo LifecycleCare service agreement. The company has just signed another agreement to cover its full fleet of Wärtsilä 18V50DF engines for the next seven years and 50,000 running hours.

“Before 2018, we didn’t have a servicing agreement,” says Charles. “We were just buying spare parts when we needed them. We found that when we had issues with the engine, it was really difficult to get replacement parts quickly, which caused a lot of operational issues with unplanned outages.

“Since we moved onto a Turbo LifecycleCare agreement, we are no longer struggling with our own supply chain, and we have access to the parts needed to fix any problems without having to store them in our warehouse. That has really helped us to focus on operations and other maintenance activities and provide a more reliable service.”

Customs clearance in Cameroon was just one of the issues facing Kribi before it signed up to a TurboLifecycle Care agreement. Import duties can be up to 40% of the value of the goods, and there can also be a lot of documentation. It can take weeks for replacement parts to pass through customs, causing further supply chain delays that can interfere with uptime.

The benefits of TurboLifecycle Care

“With TurboLifecycle Care, Accelleron takes over this side of the supply chain, so it’s a good opportunity for us,” says Charles. “We’ve benefitted from the faster reaction times that a service agreement with Accelleron offers. We had 10 hours in our initial contract, and we’ve found that engineers from Accelleron respond a lot faster, often reaching the plant and starting work on the engine in around four hours. We’ve also benefitted in terms of paperwork, with Accelleron handling the administrative side of customs clearance, so we no longer struggle to get spare parts on time.”

The latest contract continues a strong relationship between Kribi and Accelleron. “We were very satisfied with our existing contract, for starters,” Charles explains. “But our aim was to jump directly into an extended agreement, as our previous one brought so many benefits. We want to move from reactive maintenance to a more proactive approach, and signing the Turbo LifecycleCare agreement was a natural choice.”

Not only has Accelleron been able to help Kribi to maintain and run engines reliably for the past six years, safety has also been at the forefront of operations. “It’s not easy to work in a power plant,” says Charles. “There’s a lot of risk that people are exposed to, but we’ve seen that the safety culture of Accelleron is also good, and that’s really helped to remove the pressure.

“It’s a strong relationship, and we’re happy that everybody is working together to help solve issues, with Accelleron providing an efficient service that helps us to meet our targets. That's the way business should be, with both parties benefitting.”

1 International Energy Agency (October 24th 2023). The energy world is set to change significantly by 2030.

2 Power Technology (October 21st 2024). Power plant profile: Song LouLou, Cameroon.