On the road to decarbonizing the maritime sector, cleaner fuels like methanol provide obvious and immediate potential to reduce greenhouse gas (GHG) emissions. But they also present engineering challenges because of their physical and chemical differences from conventional fuels, meaning new engine concepts are required.

When the international combustion engine maker association CIMAC’s triennial congress met in Zürich in May, such issues were at the top of its agenda. Accelleron and fuel injection specialist OMT, which has been part of the Accelleron group since 2023, play a key role in enabling the clean fuel transition, and both presented multiple papers to the congress.

One paper from OMT considers low pressure (10-50 bar) port fuel injection (PFI) using methanol. This involves spraying methanol into the intake manifold to create a homogeneous mixture that burns according to the Otto cycle, with pilot diesel fuel injected at high pressure to ignite the main fuel. This allows engines to be converted to methanol operation with simpler and cheaper modifications than might otherwise be needed.

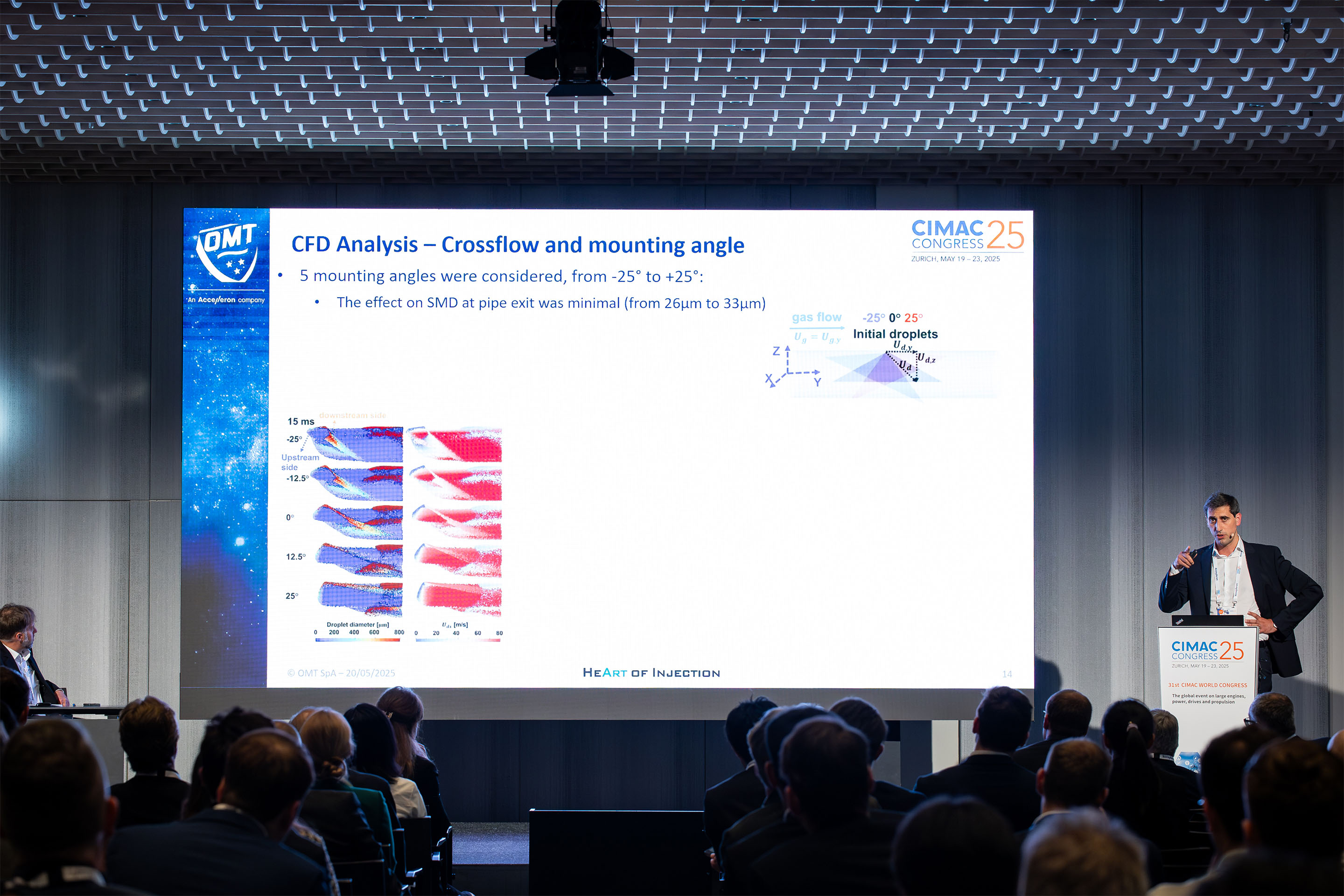

Marco Ferro presenting at CIMAC 2025

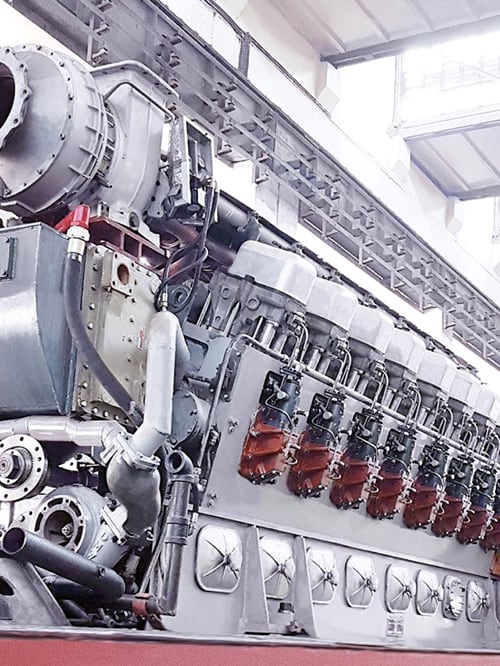

Marco Ferro told conference delegates that OMT had designed a PFI that is specifically intended for large medium speed engines. Their solution is particularly relevant because of the size of the existing fleet that will need to consider alternative fuels. OMT predicts that retrofit solutions that enable older vessels to benefit from carbon-neutral fuel use could be pivotal to accelerating the maritime energy transition and achieving net zero.

Fixing the existing fleet

Recent regulatory developments support that idea. In 2023, IMO raised international shipping’s decarbonization goals by setting GHG emissions reductions targets of 30% by 2030 and 80% by 2040 – both compared with 2008 levels – and of reaching net-zero emissions by or around 2050. These targets were further supported in April this year, when IMO’s Marine Environment Protection Committee adopted a Global Fuel Intensity Standard and pricing mechanism, which aim to deliver a scheme of penalties and incentives to reinforce those targets.

Ships now being ordered will be specified to take these goals into account, but the existing fleet will also need to comply. This will require a global program to retrofit existing engines, many of which will be fitted with new fuel injectors that can deliver the new fuels.

Marco Ferro - Cimac 2025

Marco Ferro - Cimac 2025

How it works

At its heart, the PFI has a solenoid-actuated, outward opening conical poppet valve, which produces a conical sheet of fluid that breaks up within a short distance from the nozzle. It is suitable for engines of up to 1,200kW/cyl, with each cylinder fitted with an injector. Solenoid actuation was chosen so that fuel return or control oil feeding and return lines are not needed, which simplifies the installation.

Its design ensures that all potential leakages are directed towards a dedicated line with a low positive pressure of nitrogen or in vacuum, making the injector ATEX-compliant. It also has an inbuilt flow fuse to limit the injected quantity in case of malfunctioning.

Tests were made using a dedicated test bench that was designed to validate the PFI injectors using either test oil or distilled water. A computer-aided simulation of the injector was also developed and its output agreed very closely with the test observations.

Additional physical tests were made to check the injectors’ durability, which were done on a bench that was designed by Alfa Laval to mount up to five injectors and operate them under the same conditions as would be found in an engine, in terms of injection frequency and injection duration.

Finally, injectors were installed on a multi-cylinder laboratory engine on which 350 running hours were accumulated in methanol operation during which up to 95% of the fuel used was methanol. Those tests went well; no performance or functional problems were reported by the engine maker and no significant wear or performance deviation was observed during checks on seven of the injectors after 90 running hours.

Results match simulations

Alongside these practical tests, a computational fluid dynamics (CFD) study was carried out by Accelleron’s Advanced Technology team to study the injector’s spray behavior under real-life conditions. Combining the experimental and the CFD results showed that OMT’s new PFI is a practical solution to converting existing engines to use methanol and that it can be easily installed.

What matters now is the availability of green methanol, which is made using renewable energy and non-fossil carbon. If suitable supplies can be secured, OMT’s breakthrough injector could significantly advance decarbonization over the coming years.