Fuel savings with no compromise in flexibility

Low-load operations, also known as slow steaming, is an operational measure used by many vessel operators to cut fuel costs and emissions.

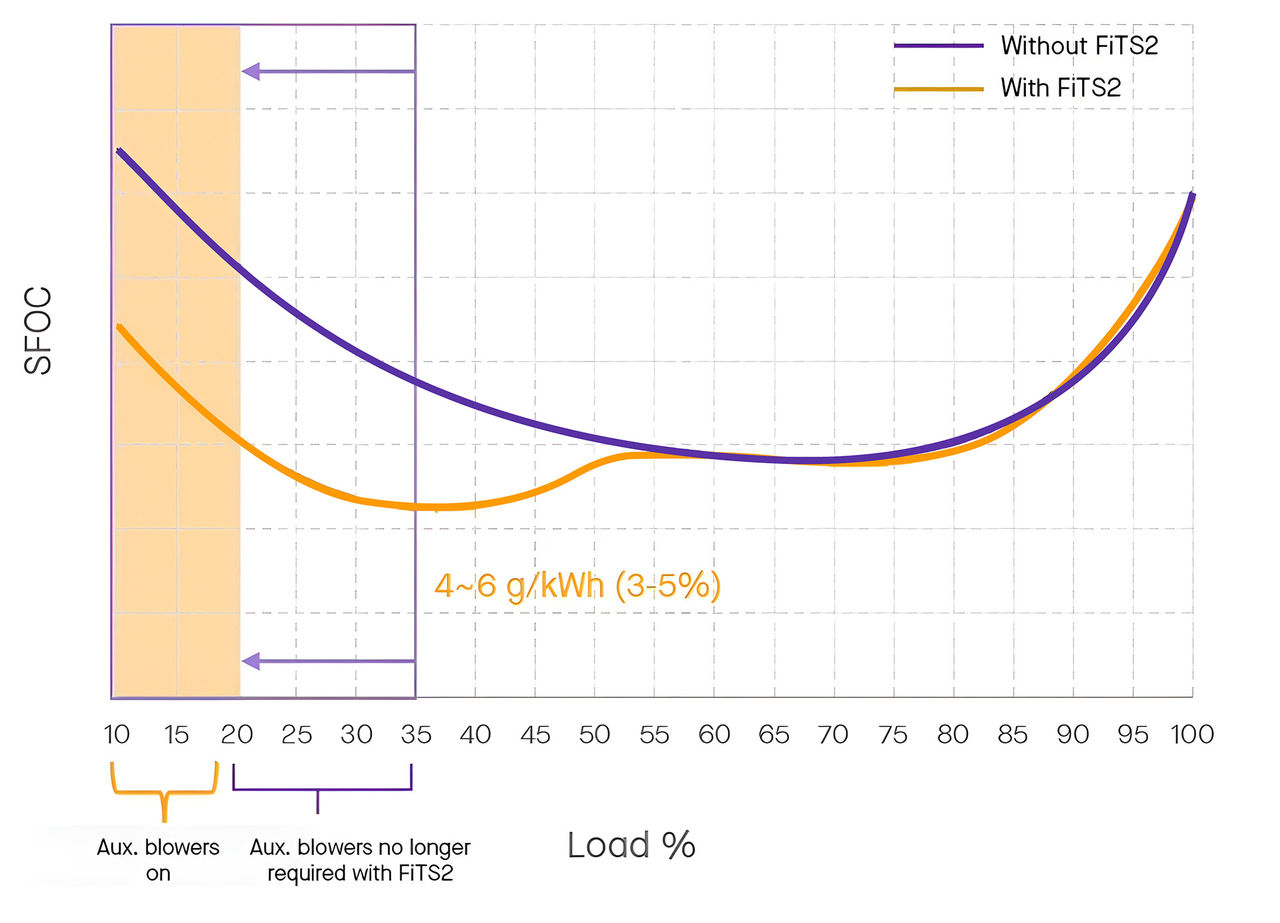

When the engine is operated outside optimum load range, specific fuel oil consumption (SFOC) increases, resulting in more fuel being used per unit of power generated, thus reducing the benefit of slow steaming.

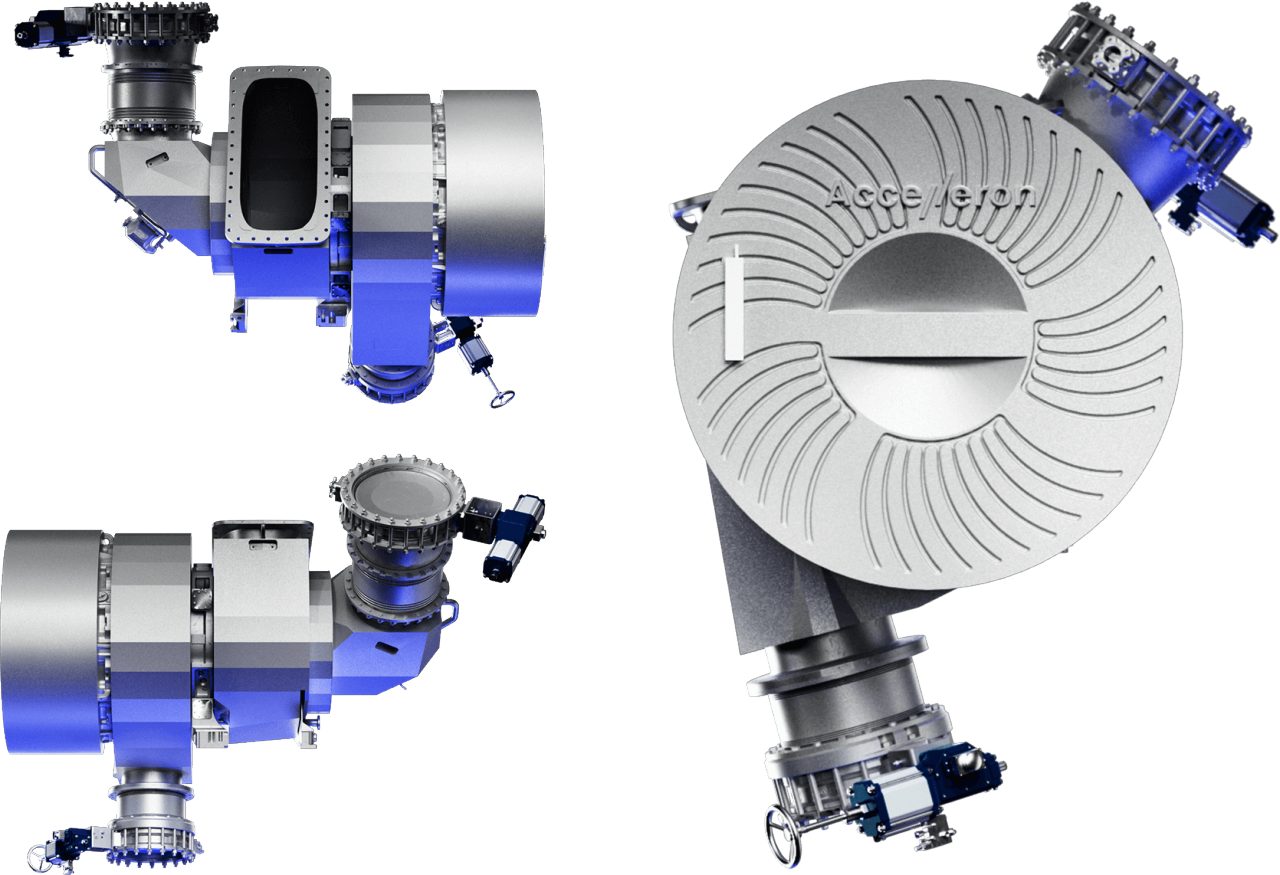

Accelleron’s Flexible integrated Turbocharging System for 2-Stroke Engines – or FiTS2 -system overcomes this issue, delivering strong fuel savings of up to 5% at part and low load. In addition, the ship retains the flexibility to go to full output without any human interaction or operational limitations.

The automatic system ensures that the potential fuel savings are realized in real life, providing operators with the financial and emissions benefits they are looking for.

What is FiTS2?

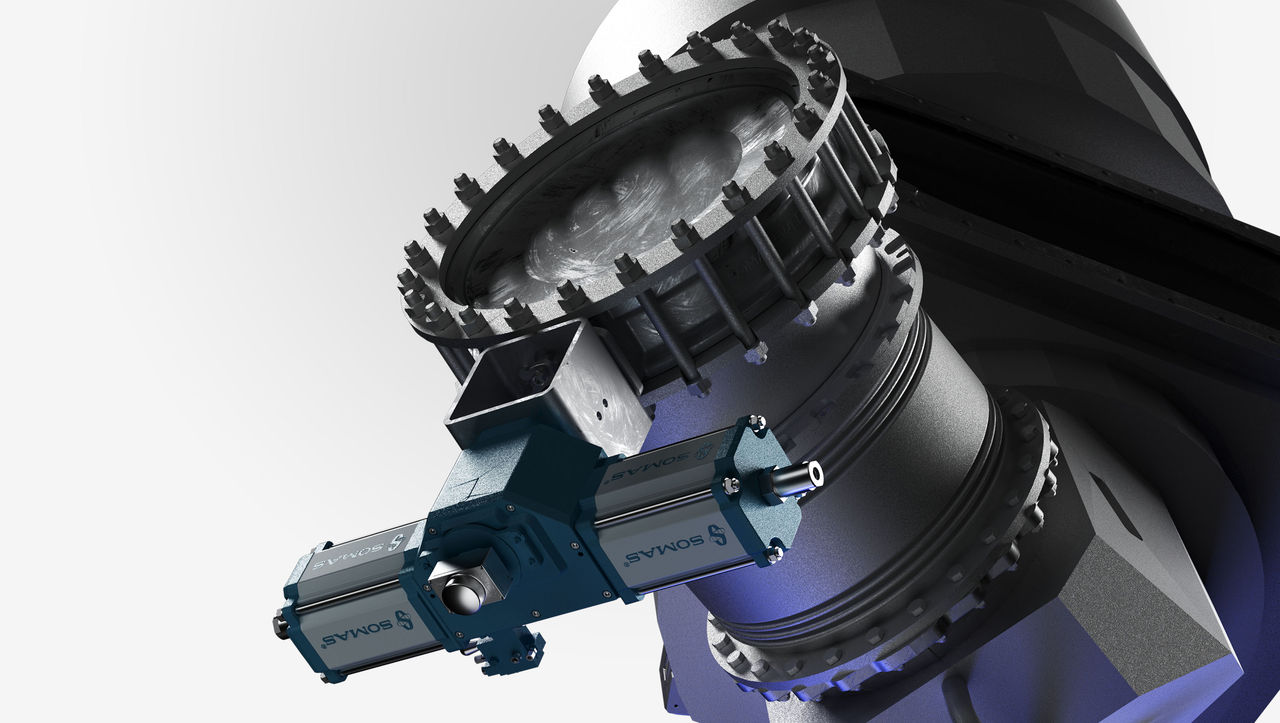

FiTS2 is a turbocharging cut-out and cut-in system for 2-stroke engines with multiple turbochargers, enabling automatic cutting in or out of the turbocharger based on the actual load and speed of the engine.

How it works

FiTS2 automatically manages the flexible activation and deactivation of turbochargers while ensuring safe and reliable operations under any conditions. It continuously communicates with the Engine Control System (ECS) and Alarm and Monitoring Systems (AMS) to ensure smooth and adaptable operation.

When engine load changes and goes below or above a pre-determined load threshold, FiTS2 automatically actuates the pneumatic valves. The system includes a fail-safe pneumatic mechanism for cut-out valves and performs a daily FiTS2 ‘gymnastic’ routine to maintain peak performance, reliability and durability.

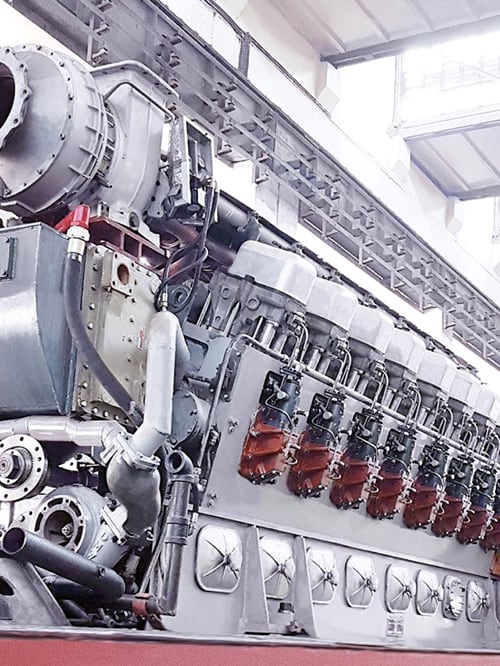

With its ability to ensure optimal performance, efficiency and flexibility, FiTS2 is the perfect solution for large 2-stroke engines with multiple turbochargers.

Why FiTS2

FiTS2 delivers fuel savings of up to 6 grams per kWh (3-5%) on the main engine compared to an engine without FiTS2. Reduced use of the main engine’s auxiliary blowers, means the system also reduces the need for power from the auxiliary engine. This decreases the running hours and lowers auxiliary engine fuel consumption.

- With FiTS2, you can automatically adapt engine performance safely with zero downtime and continue to operate the engine at full load without compromising performance.

- The fully automatic system means no additional tasks for the crew onboard.

The benefits – case study

Fuel and emissions reductions

- -5 g/kWh on main engine

- Reduced usage of auxiliary blower, switch on/off point shifted from 35% to around 20% engine load

- -1,200 tons of CO2 per year1

Full flexibility

- Automatic FiTS2 control system: Engine output can reach full load without prior load reduction, mechanical adjustments or crew handling

- Complies with IMO NOx Tier II requirements

- Pay-back time 2-4 years depending on vessel load profile

Safety and reliability

- Failsafe pneumatic system for cut-out valves

- Daily FiTS2 ‘gymnastic’ routine to prevent blockage and deposit build up

- Well proven as safe and reliable system

1 parameters :

- 50% EU ETS (in-out bound)

- 75 USD/t EU Allowances

- 600 USD/t fuel cost

- BSFC Main Engine 180 g/kWh

- BSFC Aux Engine 220 g/kWh