Engine Part-Load Optimization

Upgrade your environmental performance and efficiency

Applying EPL (Engine Power Limitation) can be an effective way of meeting EEXI (Energy Efficiency Design Index for Existing Ships) and CII (Carbon Intensity Indicator) targets.

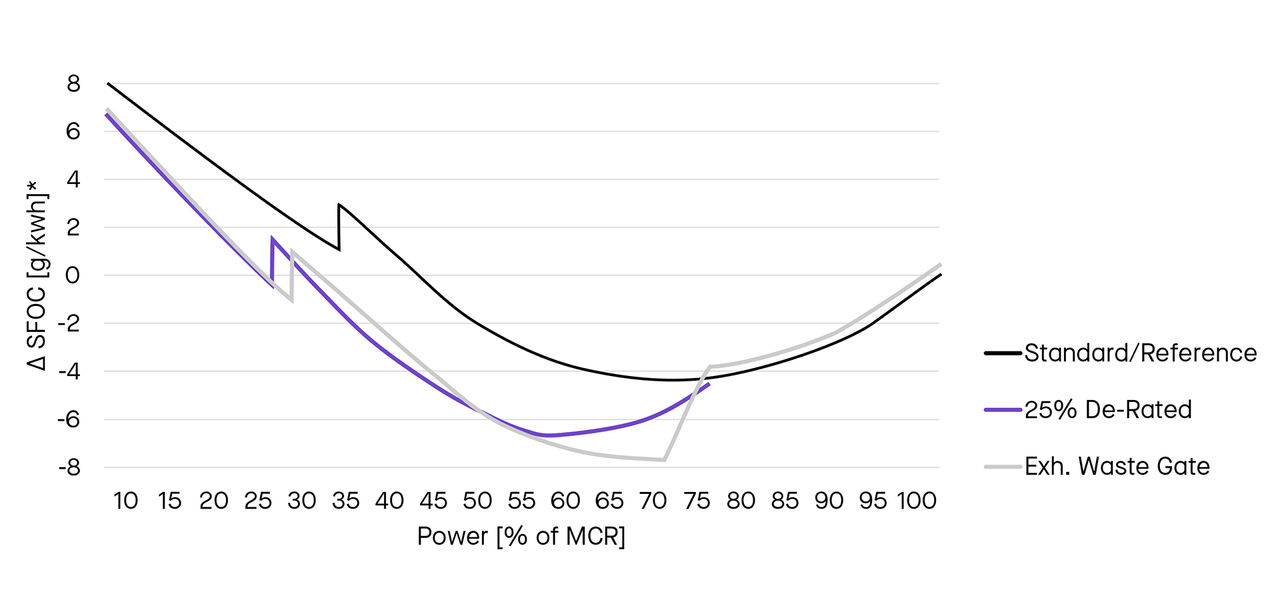

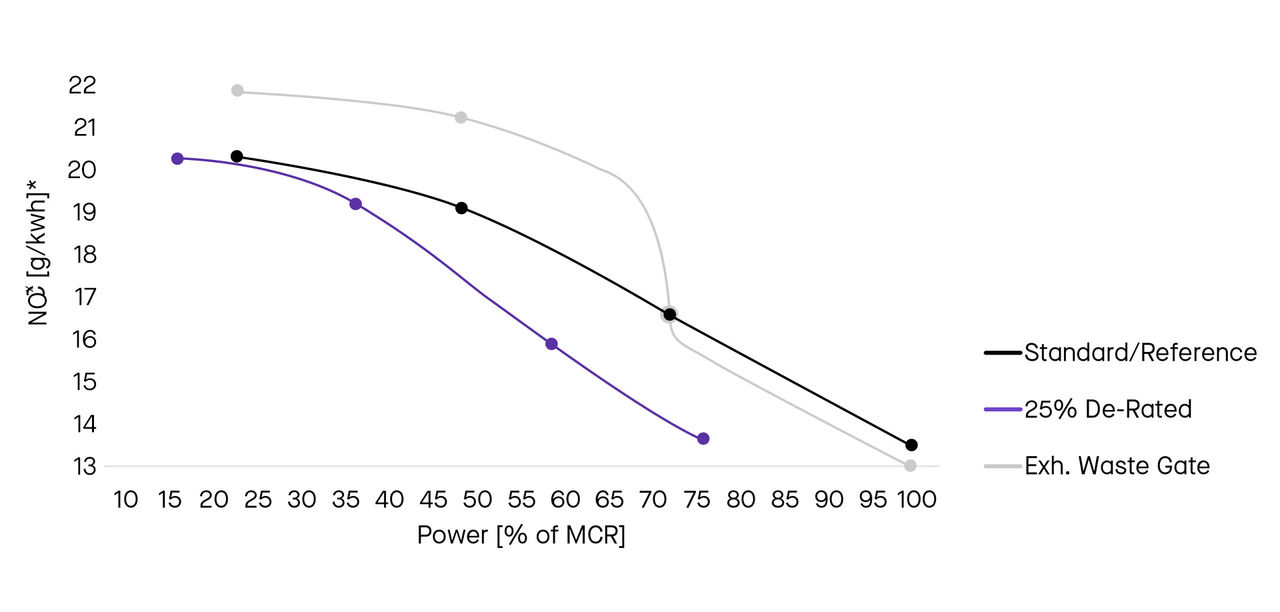

However, with EPL, the engine is operating outside of its optimal range. This leads to increased fuel consumption and reduced combustion quality. Developing a new performance concept for your engine’s operating range will overcome this, saving fuel and reducing greenhouse gas emissions. Combining our expert knowledge in engine performance tuning and turbocharger matching, we can provide you with a package that will reduce fuel consumption by 3 g/kWh up to 6 g/kWh.

We offer technical services that help you future-proof your assets and reap both environmental and commercial gains. As sustainability standards evolve, our upgrades deliver immediate reductions in fuel consumption, emissions, and operating costs.

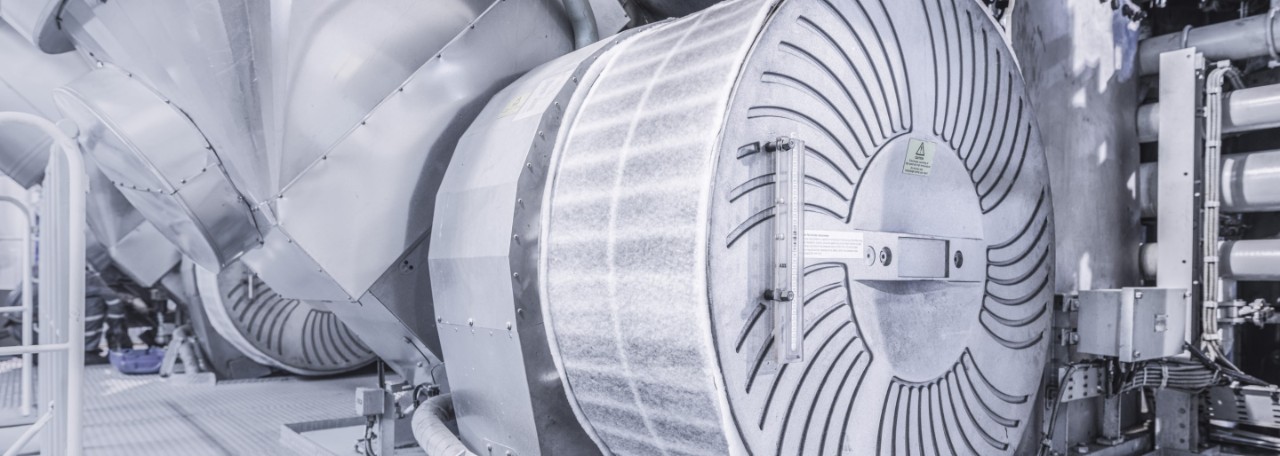

Engine part-load optimization

Operating engines at low load, Engine Part Load Optimization (EPLO) enables you to considerably reduce greenhouse gas emissions and cut fuel costs. Furthermore, reliability is improved by reducing carbon deposits and improving the combustion process.

Compare Models

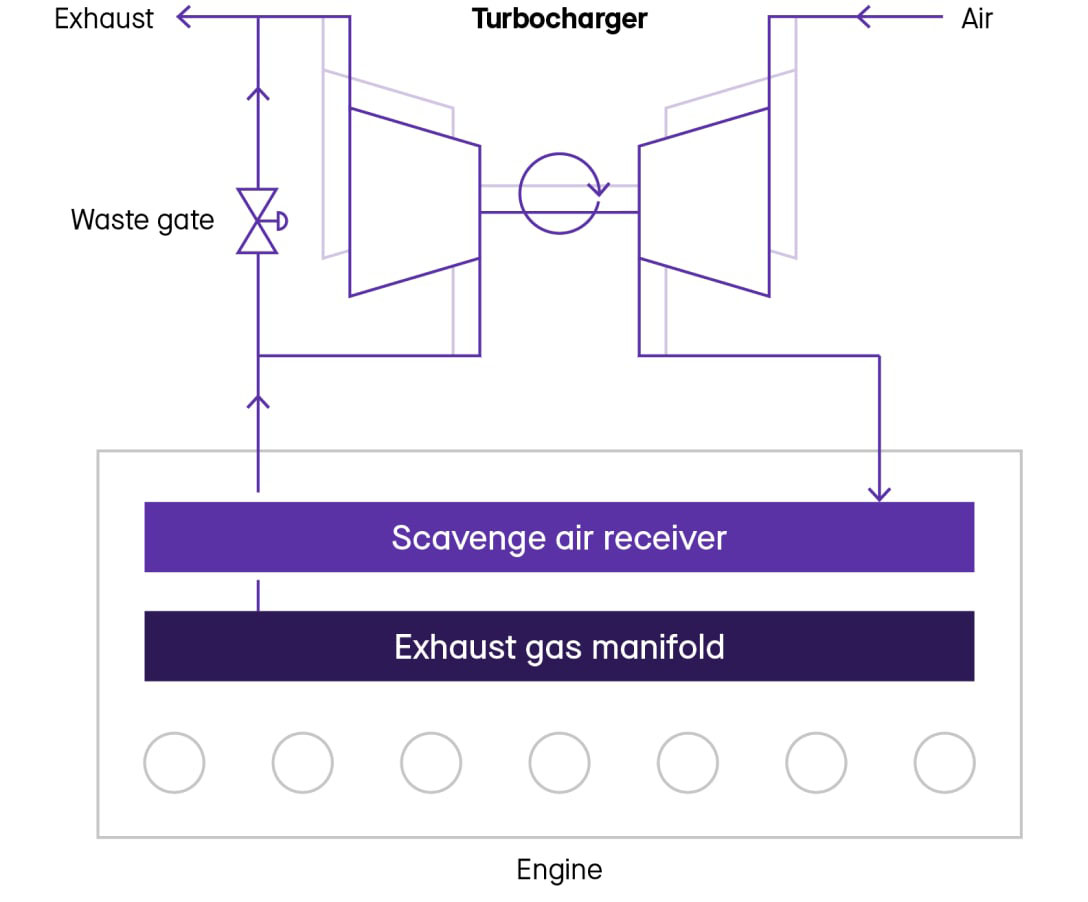

- Permanent engine derating

- Exhaust Waste Gate

Benefits of different options

We’re with you all the way

We will help you choose the right option. Whether it’s permanent engine derating, waste gate installations or simply re-matching your turbochargers to lower engine loads, we’ll find the best for your engine specification, expected load patterns, and regulatory requirements.

We’ll find the solution that gives you the most competitive payback period while meeting your upcoming CII (Carbon Intensity Indicator) ratings or as a part of your SEEMP (Ship Energy Efficiency Management Plan). We’ll lead you to the correct turnkey partner who will take you through the whole project, from finding the right solution to final engineering, including managing your IMO NOx certification and approval of the final EEXI technical file. We will guide you to ensure you remain efficient and compliant.

Related press releases

Here's a typical engine part-load optimization upgrade

- Basic engineering for applicable solutions

- Consulting to find the right package for your needs

- Consulting to find the right turnkey partner for your vessel e.g. main engine OEM, shipbuilding- or service-partners

- Detail engineering:

- Specification of engine parts required and engine tuning

- Specification of turbocharger parts, delivery, and installation

- Guiding you through the certification process

- Delivery and execution of re-matching of the turbocharger

- Execution of confirmation trial and fine tuning

- Witness of IMO NOx measurement*

- Final report including IMO NOx file* and support for the amendment to the IMO NOx Technical File

* for parent engine only