Decarbonization is challenging every maritime business, and engine designers are among the first to explore the demands that new, carbon-neutral fuels will place on ship operations. When the international combustion engine maker association CIMAC’s triennial congress met in Zürich in May, that issue was at the top of its agenda.

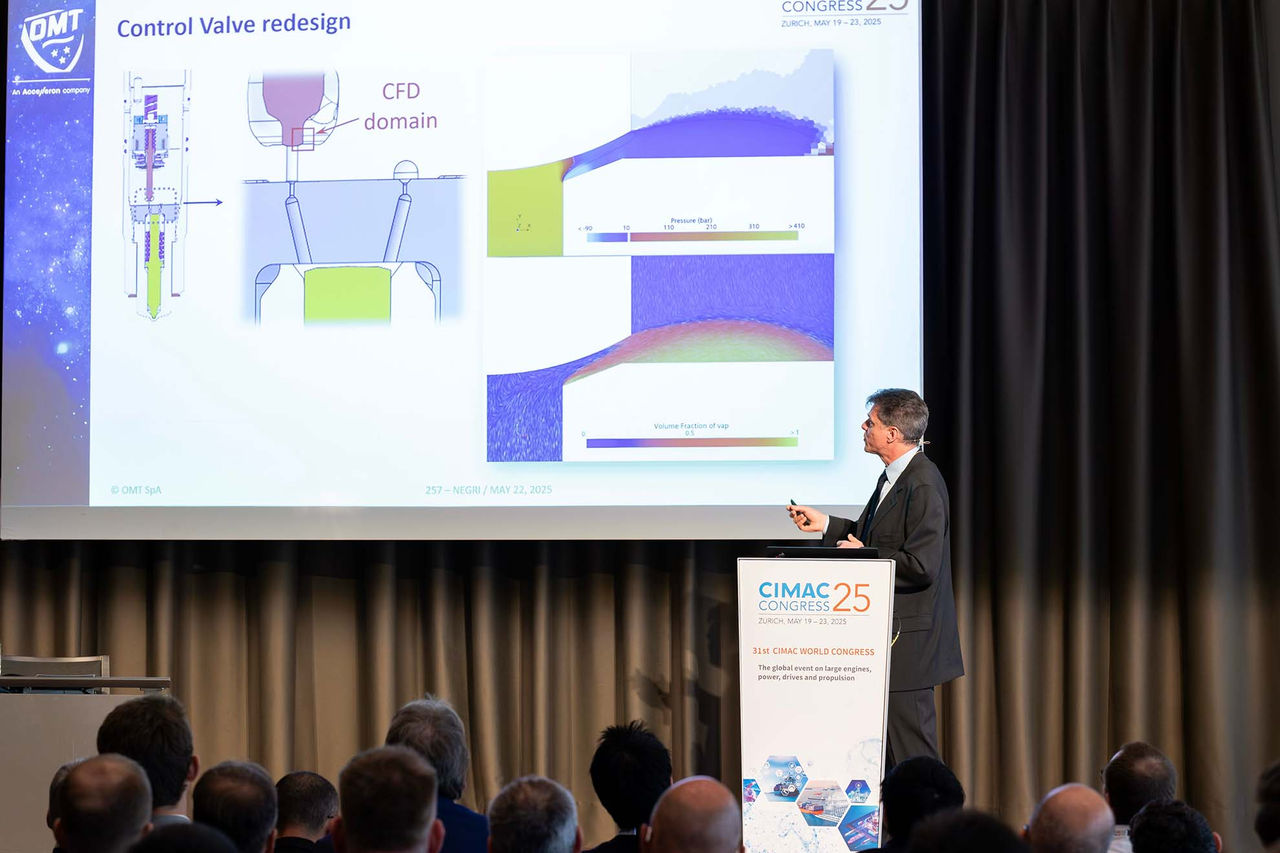

Fuel injection specialist OMT, which has been part of the Accelleron group since 2023, has a pivotal role in designing technology to enable the use of carbon-neutral fuels such as methanol and ammonia, and OMT experts were invited to present two technical papers on their latest achievements. Claudio Negri, Marco Coppo and Maximilian Malin revealed how the company had developed high-pressure fuel injectors that could simultaneously deliver ammonia or methanol alongside diesel fuel for pilot ignition or full backup power.

Claudio Negri, OMT, Accelleron, presenting at CIMAC Congress 2025

Claudio Negri, OMT, Accelleron, presenting at CIMAC Congress 2025

These developments are intended to support the International Maritime Organization’s (IMO) GHG emissions reductions targets of 30% by 2030, 80% by 2040, and net-zero emissions by around 2050. They also support a Global Fuel Intensity Standard and pricing mechanism, proposed by IMO’s Marine Environment Protection Committee in April, which aims to deliver a scheme of penalties and incentives to reinforce those targets.

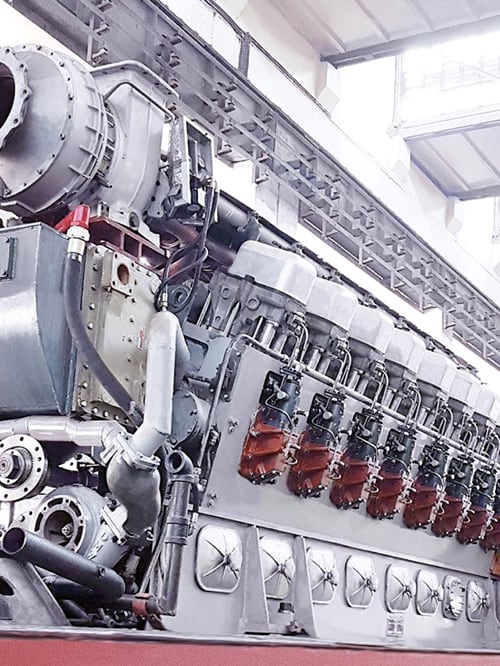

With a typical ship lifespan of 30 years, vessels built within the next decade will be responsible for delivering on the IMO targets. For deep-sea operations, since internal combustion engines will continue to be the most viable means of generating the vast power needed for propulsion, new, carbon-neutral fuels will be needed to decarbonize. Those new fuels require engines with more complex fuel injectors.

Enabling carbon-neutral fuels

Choosing methanol or ammonia as fuel, together with high-pressure injection for its delivery, is significant. Methanol is already the second-choice alternative fuel for newbuild vessels, behind liquefied natural gas (LNG), and can be made using biomass or synthesized using captured carbon dioxide and green hydrogen. Ammonia, which has no carbon in its molecule, can also be produced using green hydrogen. The first ammonia-fueled vessels are expected to be in service from 2026, with their engines being built and delivered this year.

High-pressure fuel injection enables higher cylinder compression ratios than are possible with low-pressure injection into the intake manifold, making it more fuel efficient. Furthermore, introducing the main fuel at the end of the compression stroke reduces the presence of unburnt fuel near the combustion chamber walls. This, in turn, further limits emissions and minimizes contamination of engine oil.

High pressure injection is therefore poised to be a fundamental technology that will be essential to future-proofing marine engines, and OMT’s work marks an important moment in the journey towards a future in which liquid fuels such as methanol and ammonia become mainstream. In their paper, Claudio Negri, Marco Coppo and Maximilian Malin presented a number of solutions backed by assessments of their advantages and disadvantages.

Challenges

Size and space form one of the challenges OMT’s engineers had to address. There is only one good place to locate direct fuel injectors, in the center of the combustion chamber and surrounded by the four engine valves. But there is insufficient space there to fit two separate injectors – one each for the main and pilot fuels – so fuel system suppliers have been developing dual-fuel injectors that can perform both functions from within a single body, in a space previously occupied by a single diesel injector.

These complex injectors must also factor in the different injection technologies used on engines. Solutions have to be tailormade to suit specific engine architectures. OMT’s latest high-pressure dual-fuel injectors are therefore designed to accommodate both mechanical and electronic diesel stage technology, along with a variety of control fluids used by different engine designs to actuate the carbon-neutral fuel stage.

Another consideration is ensuring that the low-pressure fuel return line is nonetheless at a high enough pressure to prevent vapor formation. And, because the fuels are toxic, these lines must be double-walled. The injectors must also be able to deliver both enough diesel fuel to operate at full power and the precise, small amount needed in pilot mode. This makes electronically controlled injectors preferable – although the paper also presented a retrofit solution where a pump line nozzle (PLN) system was used, and discussed the related challenges in controlling injection timing and quantity.

Solutions

Selecting the most suitable injector design for newbuild engines is not the same as choosing one for existing engines. For a new engine, engine designers will want to use the latest injection technologies to offer optimum performance and flexibility while, for a retrofit, the goal will be to minimize changes to the injection system so as not to affect its performance with distillate fuels, and to limit conversion costs. In both cases, the aim is to keep engine modifications to a minimum.

Two versions of the injector are described in the paper: one a hybrid injector for engines of more than 1,000kW/cyl and the other a fully electronic version for engines rated at more than 600kW/cyl. The hybrid injector was designed to match a customer’s goal of retrofitting its existing engines to enable them to operate with methanol, as well as with marine diesel oil and heavy fuel oil. High initial reliability, low conversion costs and no impact on performance in diesel mode were the main design drivers.

For the fully electronic injector, a customer wanted to convert a single-fuel engine while using its existing common-rail injection system. Controlling combustion in both diesel and carbon-neutral fuel operation while keeping the engine layout simple was a priority.

Test results

Tests for the electronic injector were conducted on a single-cylinder engine fitted with two injectors, one for pilot fuel and one for carbon-neutral fuel. While this did not match the dual-fuel injector, it was necessary because of space constraints on the test engine and still allowed the combustion process of new fuels to be studied.

Tests were conducted with both methanol and ammonia, using direct injection (DI) and port fuel injection (PFI) techniques. OMT’s researchers found that methanol DI came closest to matching traditional diesel combustion, with good cyclic stability maintained down to below 5% pilot diesel fuel. Using PFI, OMT’s experimenters had to deal with knocking – premature combustion caused by too much gas in the air-fuel mix – which they did by making adjustments to various parameters, including increasing the pilot fuel to over 30%.

With ammonia, the test results were also variable. With PFI injection, the air-ammonia mixture burns more slowly than the methanol mixture, reducing the engine’s efficiency. Tests with ammonia in the DI set-up could only be conducted up to 50% load, with researchers noting significant residual ammonia in the exhaust.

OMT’s experiments confirmed that there were pros and cons for each injection solution. With challenging fuel properties as well as demanding size and space specifications for each engine design, there will be no off-the-peg solutions for making the best use of new fuels. Those findings underline the importance of OMT’s tailor-made approach, working closely with each engine designer to deliver injection solutions customized to the unique requirements of their engines.